1) The valve body adopts the design of "waist drum", which improves the flow direction of the medium, reduces the flow resistance coefficient, and reduces the noise, and there is no noise during use. 2) The valve adopts a short structure. Although the head loss is slightly larger than that of the lift mute check valve, it is small in size and cheap in price. 3) The structure is compact, a non-metallic lubricating sleeve is installed between the guide shaft and the guide frame, and the valve disc can be raised and lowered flexibly without locking. 4) The skeleton rubber sealing ring is directly inlaid on the valve body, which avoids the direct erosion of the sealing ring by the medium for a long time, and the service life is significantly prolonged, and it is strong and durable. 5) The valve disc has a short opening and closing stroke, which can effectively prevent the occurrence of water hammer. 6), suitable for water supply and drainage system, high-rise building pipe network, can be installed at the outlet of the pump, the structure is slightly modified, can be used as a suction bottom valve, but not suitable for sewage pipe network.

Introduction

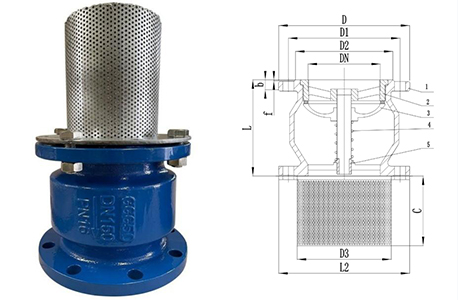

The Silent check bottom valve refers to the addition of a bottom valve filter screen at the bottom on the basis of the muffler check valve.

Silent check valve refers to a valve that automatically opens and closes the valve flap by relying on the flow of the medium itself to prevent the backflow of the medium. Drainage of container media.

Mainly based on the standard

1) Design and manufacture standard: GB/T12233-2006

2) Connection flange standard: GB/T9113-2010, GB/T17241.6-2010 (iron)

3) Structure length standard: GB/T12221-2005

4) Pressure test standard: GB/T13927-2008

Structure diagram