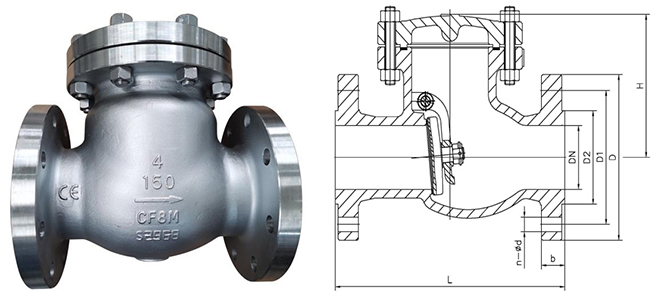

1) The swing check valve has reasonable structure, reliable sealing, small flow resistance and excellent performance. 2) Good scratch resistance and long service life. 3) Various piping flange standards and sealing surface types can be used to meet the needs of various working conditions. 4) The valve disc rotates around the pin outside the valve seat to reduce the violent impact when closing. 5) The connection between the pin shaft and the valve disc adopts a built-in structure, which is more reliable in use.

Overview

The swing check valve is a kind of check valve that the valve flap opens and closes with the upward rotation of the rocker arm, which can automatically prevent the backflow of the fluid. The disc of the check valve swings upward under the action of fluid pressure, and the fluid flows from the inlet side to the outlet side. When the pressure on the inlet side is lower than that on the outlet side, the valve disc will automatically close under the action of fluid pressure difference, gravity and other factors to prevent the fluid from flowing back.

Main technical parameters

|

Nominal pressure (Mpa) |

Strength test MPa |

Seal test MPa |

Applicable temperature (℃) |

Applicable medium |

|

1.0 |

1.5 |

1.1 |

≤350℃ |

Cast steel: water, air, oil Stainless steel: weak corrosive medium |

|

1.6 |

2.4 |

1.76 |

||

|

2.5 |

3.75 |

2.75 |

||

|

4.0 |

6.0 |

4.4 |

||

|

6.4 |

9.6 |

7.04 |

Material of main parts

|

Part name |

Material |

|

Body |

WCB, stainless steel |

|

Bonnet |

WCB, stainless steel |

|

Seal ring |

graphite+304 |

|

Disc |

WCB+Stainless Steel,Stainless Steel |

|

Rocker arm |

WCB, stainless steel |

Structure diagram