1) The fluid resistance is small, and the full-bore ball valve basically has no flow resistance. 2) It adopts threaded connection, with simple structure, small size and light weight. 3) Tight and reliable, the valve seat is made of PTFE, which has good sealing performance and can achieve complete sealing. 4) Easy to operate, quick to open and close, just rotate 90° from fully open to fully closed. 5) It is easy to maintain, the structure of the ball valve is simple, the sealing ring is generally movable, and it is more convenient to disassemble and replace. 6) When fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium, and the sealing surface of the valve will not be eroded when the medium passes through. 7) Wide range of applications, with diameters ranging from small to several millimeters to several meters, and can be applied from high vacuum to high pressure. 8) Since the ball valve has wiping properties during the opening and closing process, it can be used in the medium with suspended solid particles.

Overview

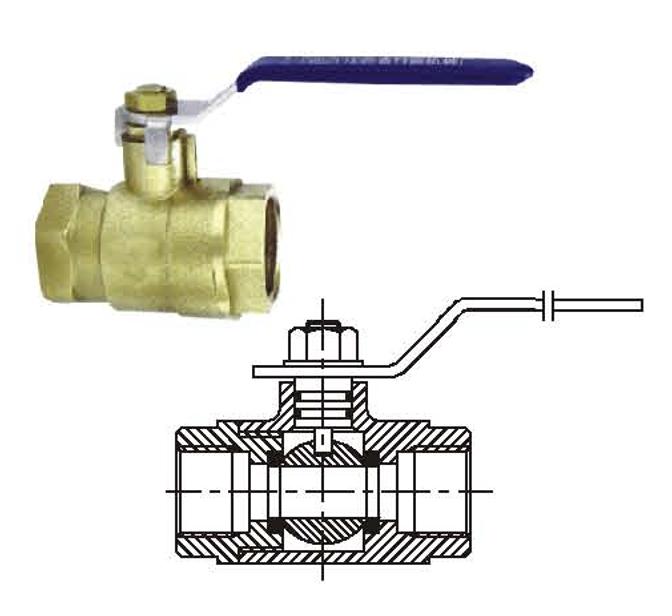

Q11F threaded ball valve is divided into one-piece ball valve, two-piece ball valve, three-piece ball valve, etc. The ball rotates around the center line of the valve body to achieve opening and closing. The ball valve is mainly used to cut off and adjust the flow in the pipeline. Two-piece ball valve and three-piece ball valve are a new type of valve that has been widely used in recent years.

According to the standard

1) Design and manufacture standard: JB/T8464-2008

2) Structure length standard: GB/T12221-2005

3) Pressure test standard: GB/T13927-2008

Main performance specifications

|

Nominal pressure PN (MPa) |

Test pressure MPa |

Working temperature (℃) |

Applicable medium |

|

|

case |

seal |

|||

|

1.0 |

1.5 |

1.1 |

≤150 |

water, air, oil |

|

1.6 |

2.4 |

1.76 |

||

Material of main parts

|

Body, Bonnet |

Copper |

|

Sphere |

Copper |

|

Stem |

2Cr13 |

|

Seat |

PTFE |

|

Packing |

PTFE |

Structure