1) Small fluid resistance The medium channel inside the gate valve body is straight, and the medium does not change its flow direction when it flows through the gate valve, so the flow resistance is small; 2) Opening and closing is more labor-saving. When opening and closing, the movement direction of the gate is perpendicular to the medium flow direction, and the opening and closing of the gate valve is more labor-saving; 3) The flow direction of the medium is generally unrestricted. The medium can flow in any direction on both sides of the gate valve, which can achieve the purpose of connecting or cutting off, which is convenient for installation and is suitable for pipelines where the flow direction of the medium may change; 4) There is a guide mechanism on the valve body of the small gate valve, which can prevent the gate from rotating when opening or closing, so as to ensure the corresponding alignment of the sealing surface and prevent the gate from rubbing against the valve seat before reaching the closed position. Thereby reducing the wear of the sealing surface; 5) Simple structure The shape and structure of the gate valve are relatively simple, and the manufacturing process is good; 6) Low cost Due to the threaded connection, the structure is short and the shape is small; 7) The structure is short and small. The valve adopts a dark rod structure, which has small dimensions and is easy to install.

Overview

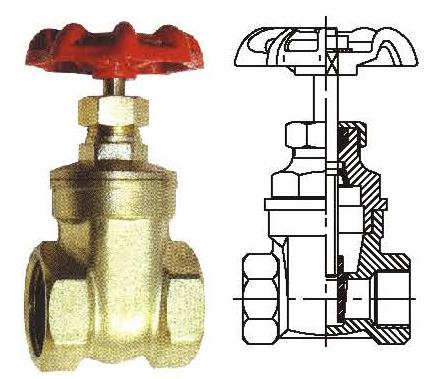

Cast iron threaded gate valve: Gate valve refers to a valve whose closing member (gate) moves in the vertical direction of the channel axis. It is mainly used to cut off the medium on the pipeline, that is, fully open or fully closed. The connection method is threaded, and the material is cast iron valve.

Implement the standard

Manufacturing standard: GB/T8464-2008

Structure length standard: GB/T12221-2005

Material standard: GB/T12227-2005, GB/T9440-2010

Main technical parameters

|

Nominal pressure (Mpa) |

Strength test MPa |

Seal test MPa |

Applicable temperature (℃) |

Applicable medium |

|

1.0 |

1.5 |

1.1 |

≤200℃ |

water, air, oil |

|

1.6 |

2.4 |

1.76 |

Structure