1) Small friction In the process of opening and closing, the friction between the valve disc and the sealing surface of the valve body is relatively small, and it is smaller than that of the gate valve, so it is wear-resistant; 2) The opening and closing height is small, and the opening height is generally only 1/4 of the diameter of the valve seat channel; 3) Good sealing performance. Usually, there is only one sealing surface on the valve body and the valve disc, so the manufacturing process is better and it is easy to maintain; 4) Precision casting valve body The valve body adopts precision casting, and the precise geometric size enables the valve body to ensure the sealing performance of the valve without any finishing; 5) The small size valve adopts threaded connection, which is small in size, light in weight and easy to install.

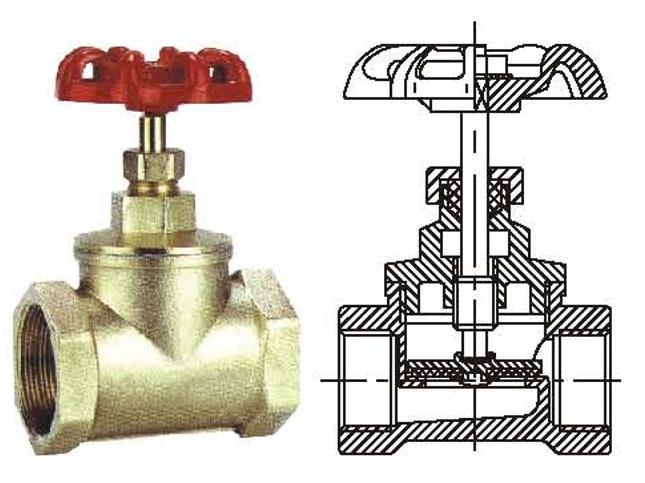

Product overview

The globe valve is a valve whose closing member moves along the center line of the valve seat. The valve has a relatively short opening or closing stroke of the valve stem, and has a very reliable cut-off function. The stroke is proportional to the relationship, and can be used for adjustment on fluid pipelines such as tap water, sewage, construction, food, electricity, medicine, metallurgy, light textiles, and energy systems.

Main technical parameters

|

Nominal pressure (Mpa) |

Strength test MPa |

Seal test MPa |

Applicable temperature (℃) |

Applicable medium |

|

1.0 |

1.5 |

1.1 |

≤150℃ |

water, air, steam, oil |

|

1.6 |

2.4 |

1.76 |

Material of main parts

|

Part Name |

Material |

|

Body |

Copper |

|

Bonnet |

Copper |

|

Stem |

2Cr13 |

|

Seal ring (gasket) |

Graphite/PTFE |

|

Filler |

Graphite/PTFE |

Structure