1) Integral rubber-coated gate: The ductile iron skeleton is covered with high-performance rubber and the latest vulcanization technology inside and outside. 2) One-piece copper nut: The copper nut of the valve stem and the ductile iron bracket are tightly connected together by a special process to ensure that they will not be loosened under long-term operation and avoid the control failure of the valve. 3), flat and low valve seat, the bottom of the elastic seat seal gate valve adopts a full flow channel straight-through design, which is equivalent to a straight pipeline, and it is not easy to accumulate debris, so as to ensure reliable sealing and unobstructed fluid flow. 4) Lightweight structure: The compact structure reduces the maximum working height by more than 60mm to 300mm compared with the traditional gate valve, saving engineering space; the body is made of ductile iron material, and the weight is reduced by about 20% to 30% compared with the traditional gate valve, and the installation and maintenance are convenient. 5) Corrosion resistance: The inner and outer surfaces of the valve are painted with epoxy resin powder, and the inner parts are made of stainless steel and copper alloy to prevent rust and fluid corrosion. 6) Four seals are used to completely eliminate the leakage of the valve: the first seal, the upper seal of the valve stem and the valve cover, is sealed with high-quality O-rings; the second seal is between the valve cover and the valve body. Special sealing ring is used; high-quality O-ring is used between the third valve stem and the stuffing box; high-quality O-ring is used between the fourth valve stem and the packing gland bracket. 7) The valve stem is made of high-quality stainless steel, and the hardness of the valve stem reaches HB200-275 after quenching and tempering treatment, which not only ensures the strength of the valve stem, but also increases the wear resistance of the valve stem. 8) The valve is sealed in both directions and can be installed in any position of the pipeline. 9) The manual actuator is hand wheel, which can be replaced with gear, electric and other actuators.

Product overview

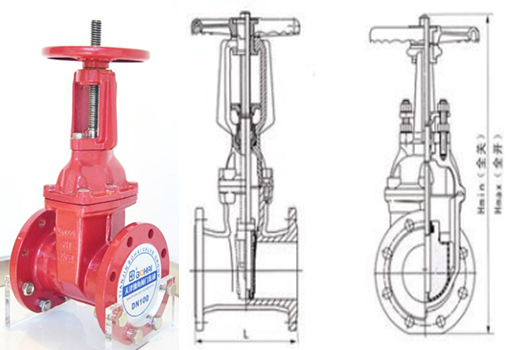

The opening and closing part of the open rod elastic seat gate valve is the gate. The movement direction of the gate is perpendicular to the direction of the fluid. The gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled. The valve uses the compensation effect of the elastic gate to produce a small amount of deformation to achieve a good sealing effect. It can be widely used in tap water, sewage, construction, food, electricity, medicine, metallurgy, textile, energy systems and other fluid pipelines as a shut-off device use.

Main reference standards

1) Design and manufacture standard: CJ/T216-2013

2) Connection flange standard: GB/T9113-2010, GB/T17241.6-2010 (iron)

3) Structure length standard: GB/T12221-2005

4) Pressure test standard: GB/T13927-2008

Main technical parameters

|

Nominal pressure (Mpa) |

Shell test pressure MPa |

Sealing test pressure MPa |

Applicable temperature (℃) |

Applicable medium |

|

1.0 |

1.5 |

1.1 |

≤80℃ |

water, oil, etc. |

|

1.6 |

2.4 |

1.76 |

||

|

2.5 |

3.75 |

2.75 |

Struarure

Material of main parts

|

NO |

Name |

Material |

|

1 |

Stem |

Stainless steel |

|

2 |

O-ring seal |

EPDM |

|

3 |

Bonnet |

Ductile iron, cast steel, stainless steel |

|

4 |

Stem Nut |

copper alloy |

|

5 |

Wedge disc |

Ductile iron clad EPDM |

|

6 |

Body |

Ductile iron, cast steel, stainless steel |

|

7 |

Open loop |

copper alloy |

|

8 |

Gland |

Ductile iron, cast steel, stainless steel |

|

9 |

Yoke |

Ductile iron, cast steel, stainless steel |