1), double eccentric structure, the butterfly plate and the valve seat contact or separate instantly, basically zero wear; 2) The valve has a self-locking function. When the butterfly plate is closed to the sealing position, the self-locking is realized immediately, and the failure of the butterfly plate closing over-position will not occur; 3) The butterfly plate has a streamlined design, small flow resistance, good hydraulic characteristics, and the flow characteristics are similar to inclined straight lines, and the energy saving effect is good; 4) The medium can be closed and cut off, and the flow of the medium can also be adjusted arbitrarily. 5) The valve plate sealing ring is made of high-quality rubber, with high elasticity, the sealing surface of the valve body is sealed with stainless steel, the stainless steel valve seat material has good scratch resistance, the sealing pair is combined with soft and hard, cavitation resistance and hardness stability, The test proves that under the pressure of 1.6Mpa, the valve is continuously opened 25,000 times without scratches, which greatly improves the service life of the valve 6) The valve stem of the large-size valve adopts copper alloy rolling ball bearing, which prevents the corrosion between the valve stem and the bearing, and reduces the operating torque of the valve, so that the user can control it easily and freely 7) The material of the valve stem bushing is made of copper alloy, which not only ensures the position of the valve stem, but also avoids the locking between the valve stem and the bushing due to corrosion, and reduces the operating torque of the valve stem. 8) The inside and outside of the valve is sprayed with sanitary epoxy paint, which has strong corrosion resistance and no pollution. 9) The actuator adopts a worm gear reducer, which is easy to operate and labor-saving.

Introduction

Eccentric soft sealing flange butterfly valve is a kind of rubber sealing valve with double eccentric flange connection whose valve shaft is deviated from the center line of the valve and the center surface of the valve seat is deviated from the center. It is used for water supply and drainage in other systems, especially for tap water pipelines, as adjustment and interception equipment.

Implement the standard

1) Design and manufacture standard: GB/T12238-2008

2) Connection flange standard: GB/T9113-2010, GB/T17241.6-2010

3) Structure length standard: GB/T12221-2005

4) Pressure test standard: GB/T13927-2008

Main technical parameters

Nominal pressure (Mpa) | Strength test MPa | Seal test MPa | Applicable temperature (℃) | Applicable medium |

1.0 | 1.5 | 1.1

| ≤80℃ | water, steam, oil, etc. |

1.6 | 2.4 | 1.76 | ||

2.5 | 3.8 | 2.75 |

Material of main parts

Body | Butterfly | Stem | Sealing ring | Filler |

Ductile iron, cast steel | Ductile iron, cast steel, stainless steel | Stainless steel | EPDM、NBR | Flexible graphite, EPDM |

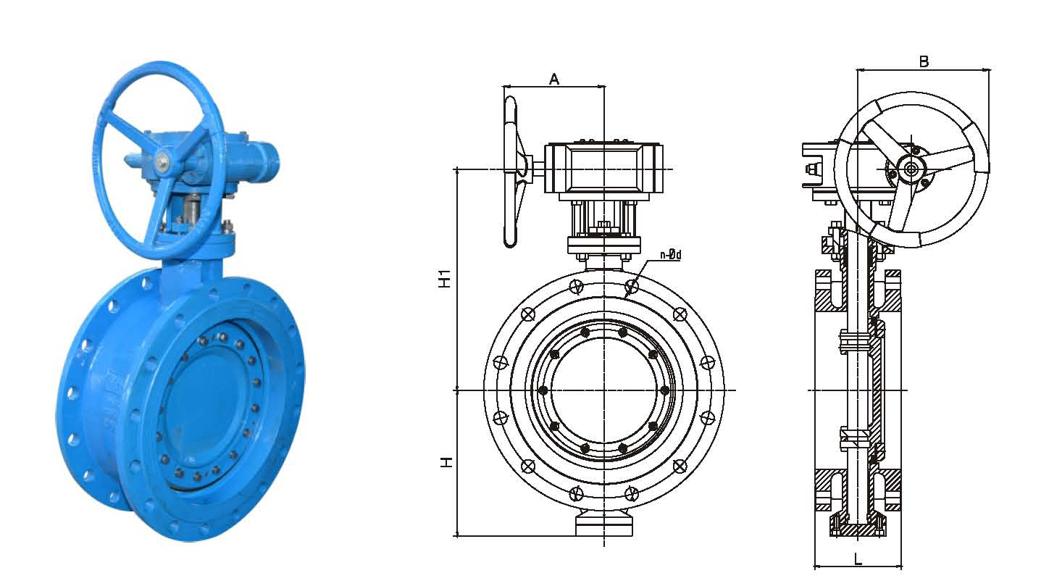

Structure diagram